Billiard/Snooker Table Beds

Prior to 1826 Billiard tables

(when I mention a billiard table you can substitute the word

Snooker!!) had wooden beds. These beds were by no means level and

it is recorded that Thurston sent out their fitters to 'flog' the

bed i.e. they went and tried to plane off the high spots. An

example of a full size wooden bed is in the Collection and there is

also an 8ft portable table with a wooden bed.

Full size wood bed ,

showing both playing surface and underside of the

sections

Thurston 8ft. portable Billiard

table with wood bed

There is evidence that experiments were being carried out in to

materials to replace the wood beds as a table that Thurston has in

stock circa 1820 has a concrete type bed which has a wood surround

so that the cushions can be bolted on. The table is either a Gillow

or and early Thurston based on the leg style .

Table No. 11556 which has a

composition/concrete bed with wood surround. (This table is

currently [2012] in Thurston's stock of antique tables ready to be

refurbished)

However slate proved to be the most suitable as the both the top

and base surfaces could be worked smooth, it was relatively easy to

fit the cushion nuts into the depth of the slate and also to drill

holes through it to secure the slate lining. The original slate

beds tended to be of similar thickness as the wood beds they

replaced which meant they were about 1 inch (25mm). This meant that

the slates required greater support as this thickness meant they

could easily go hollow.

The problem with these thin slates was

brought to the attention of players once rubber was used in the

cushions especially when they were compared to tables that had the

thicker slate beds. The reason was that the thin slate did not give

sufficient support to the cushion. In other words the cushions were

not solid on to the slate and so when the balls struck the cushion

some of the impact was absorbed by the cushion moving. The answer

was either to fit new slates, an expensive job, or to fit the newly

patented 'steel block' cushions ( 1886) or the Thurston 'Adament

'cushion. These cushion being heavy gave a solid foundation for the

cushion rubber and so the response from the such cushions improved

the playing characteristics of the table without the necessity of

replacing the slates.

Thurston 'Adament' Cushion with

a slate in fill to body

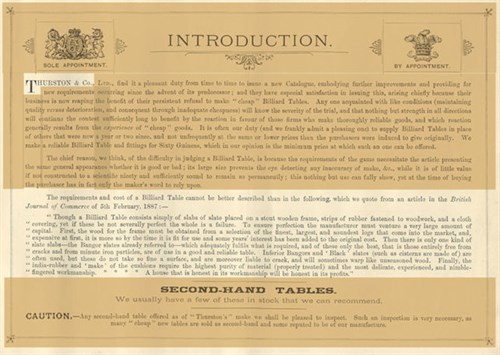

Interestingly it seems that the Bangor

slate from the Penryhn quarries was held in high esteem as two

mentions in catalogues extol its virtues.

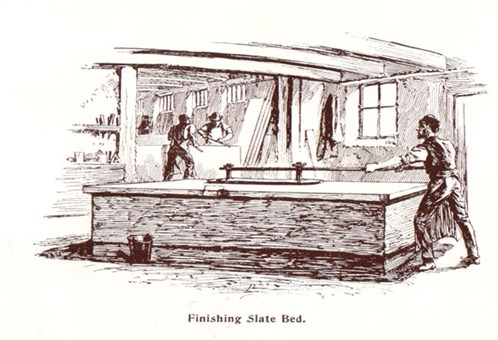

From the Thurston booklet "The Noble Game of Billiards"

published in 1908 - the following is an extract - "Within the

spacious yard one sees the ponderous slabs (sic slate) in mighty

stacks awaiting their turn to entre the busy shed where their

uneven surfaces shall be smooth, and their rough places plain. Many

soft and friabble slate are found in this country which are freely

used in the construction of cheap billard tables. The slates which

command the highest price in the market by reason of their density,

hardness, and uniformity, are those from Lord Penryhn's quarries at

Bangor, and Thurston's is the only Billiard firm supplied

direct".

The early Welsh slate as described

seems to need a fair bit of work to be carried out on it once it

was delivered to the Billiard works and 'floating' the slates was a

common requirement. This involved pushing and pulling a heavy steel

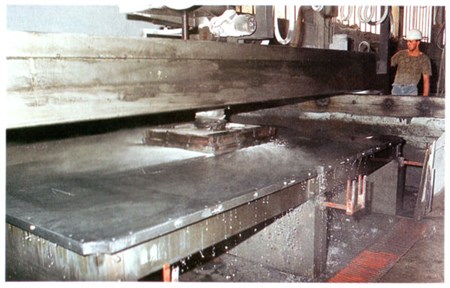

open latices device back and forth across the surface. As shown in

the picture below.

In fact even up to the late 1980's

Thurston still 'floated' some new slates - the reason being that if

the slates were shipped before they had fully seasoned the slate

sometimes moved slightly and so the 'floating' ensured that there

was no lipping at the joints. The floating in the 1980's involved

using a special non silica compound as the abrasive and a lot of

hard work pushing the float back a forth whilst ensuring that it

was done evenly.

R. Campbell hand floating a Full

Snooker Table

Over the years the slate thickness was increased until an

optimum that gave rigidity and stability but without making the

slabs so heavy as to be impossible to move meant that the modern

slates are 1 ¾ inches thick (45mm).

It seems that between WWI and WWII the slate demand being less

meant that cheaper sources of suitable slate were examined and so

Italian slate became the norm for table beds right up to the late

1990's. It is also suggested that as Welsh slate was harder that

Italian and was still blasted out of the quarries they couldn't

control the size of the pieces whereas the Italian slate could be

cut out of the quarries and thus the sizes could be more readily

controlled, meaning less waste. I also understand that in general

the Welsh slate used for Billiard tables was a type of slate

unsuitable for roofing slate as it would not cleave and so was to

some extent considered to not be worth mining when demand fell

after WW I.

As previously mentioned since the 1930's most slate used in

Billiard / Snooker tables has been Italian slate and they supplied

not only the UK market but also the World market for slate for all

the Billiard games. So the Italian quarries invested in machines to

improve the production and quality of the slates they supplied. The

following pictures are taken from Italardesia catalogue

circa 1982.

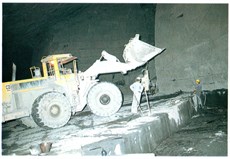

talian slate is quarried from

vast underground layers. The slate veins lie between two sandstone

layers making up the floor and roof. The slate veins are cut into

to mmake blocks of different sizes as required for the different

demands.

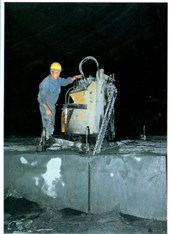

Aspecial hydraulic chain saw cuts

the blocks out of the layer. The blocks are extracted by a huge CAT

and taken out of the quarry. The blocks must be kept moist and so

are wrapped in plastic until they are sawn. It is important to

protect the blocks from drying out, otherwise they become brittle

and are useless.

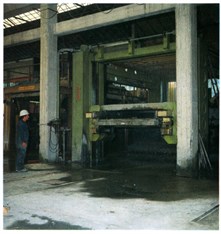

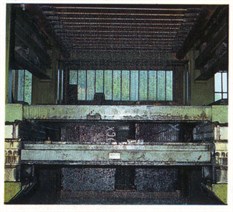

Slate finishing is a multi stage

process. The first stage is cutting the blocks with a gang saw.

Each gang saw can have 10 to 25 diamond toothed long blades. The

second picture shows a close up of a block being sawn. The

gang saw can handle blocks up to 9ft. long by 6ft wide. The slabes

are cut approx. 1/8th inch thicker than desired finished

thickness.

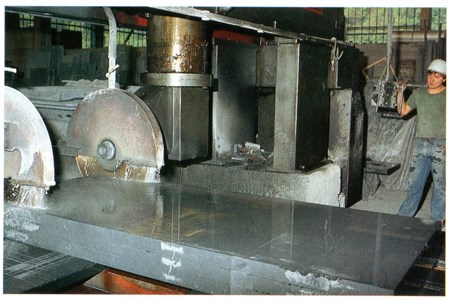

After a first curing period the

raw slabs are cut to the exact size desired by computerised sawing

machines. Both sides of each batch of slabs are cut at the same

time by twin circular saws, so as to ensure perfectly parallel

cut.

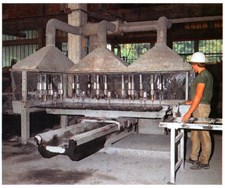

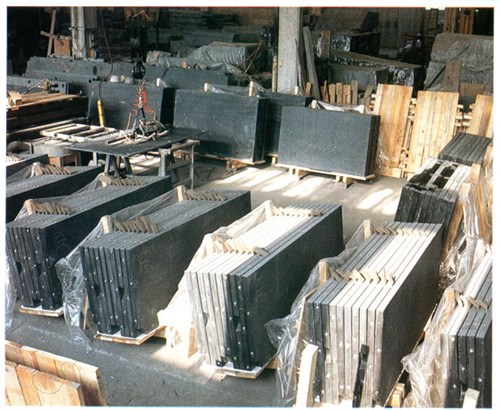

The trimmed sections are now

assembled together into a complete set of billiard slates in order

to fix dowles, drill screw holes and bolts holes for a full sized

snooker table. Sections of the slates are drilled automatically

after being assembled as a complete set, in order to ensure

accurate location of the holes as per specifications.

Pockets must be cut one by one with

diamond teeth bits, which have the required angle leaving the edges

of the pockets smoothly rounded off.

The set complete with dowles,

pocket openings, bolts etc. is then carefully 'floated' to obtain

the perfectly flat, smooth surface required for the game.

Slates waiting final inspection

before packing

The most important step after floating

is the final curing process which last for several weeks. Until the

slate is perfectly dry. Before packing the slate is again checked

and only a perfect product leave the factory.

When there was a spike in the demand for Snooker tables in the

late 1980's early 1990's the price of slate went up quite

dramatically as production was not able to keep up with the demand.

So other materials were again tried, for example float glass was

used for a time by Rex Williams leisure inn their UK Pool Tables.

It did not prove successful and a more recent example of such a

glass bed is in the collection. Other material were tied such as

resin and granite, resin and slate dust but such beds faced two

main problems the thickness to size of slab proved to be a problem

also whilst it was possible to get one good surface it didn't seem

practical from a cost point to achieve both the top and back

surfaces to be smooth and level. So despite many attempts no

replacement for slate was found.

In more recent years cheaper slate has been sourced from China

but when used in the championship tables they have selected a 2

inch (50mm) slate. It could be that they need the extra thickness

to ensure that it stays flat as the extra weight will make handling

and delivery more difficult. In Europe the Carom Billiard tables

have for a long number of years had a 50mm thick slate but the

slabs are smaller and therefore are easier to handle than a 50mm

Full size Snooker table slab.

acknowledgement - Italardesia - for pictures

and descriptions of processes

© E.A. Clare & Son Ltd.

2022. © Peter N. Clare 2022

Reproduction of this article allowed only with the permission from

E.A. Clare & Son Ltd.

thurston.co.uk - the e-shop for all your Snooker, Pool

& Billiard equipment

or Just

call +44(0)151 482 2700 or visit

www.thurston.co.uk

******************