Billiard Cloth

The 'Baize' is really Pure Wool Cloth

When you hear or read the cloth that

covers the slate and cushions of a Snooker (Billiard) table

described as BAIZE you can almost hear the sharp intake of breath

in Stroud (West of England - Strachan) and Pudsey (Hainsworth)

where the last mills in the UK that produce Billiard / Snooker

cloth are based. Why the intake of breath - well baize is a wool

/cotton mix material used for covering card tables and notice

boards, whereas the cloth used on Snooker tables is a specialist

quality pure wool material with a raised nap and is a much more

costly engineered product. A far superior material than baize!

The UK Billiards & Snooker cloth, unlike the worsted cloth

used on European and USA style Billiard and Pool tables has a nap.

One theory for this was that the cloth used for the cloaks worn by

the drivers of horse drawn coaches had a nap that ran from the

shoulders to the bottom of the cape. This encourage the rain to

flow off the cape which would have kept the coachman drier for

longer. This theory speculates that the same cloth used for the

coachmen's capes, which according to the theory was also green in

colour proved to be acceptable for UK style Billiard tables. Mind

you the other theory as to why the cloth is green relates to the

Billiards being played on a lawn on the ground, so when the game

was brought indoors on to a table the cloth covering the table was

the same colour as the 'grass'!

In the early days the finest wool was imported from Germany - in

an article recording 'A Visit to Hunts & Co's' mills it reports

- "It would seem, then, that the fineness of German wool is due

not to any peculiarity in type of breeding or feeding of the sheep,

but simply to the fact that the animals are under fed".

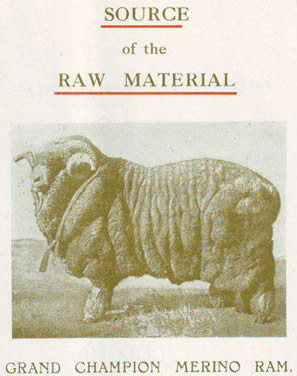

However as a result of WW1 it was the Merino sheep's fleeces from

Australia that became the source of the fine quality wool required

for Billiard cloth.

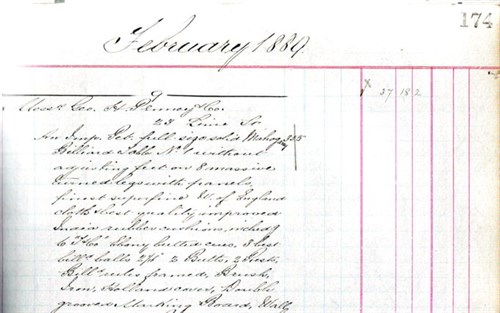

In the 'old' Thurston ledgers there are many references to 'Best

West of England' cloth an example is shown below and you will see

from the date that Thurston have been buying Billiard

cloth from the 'West of England ' mills based in Stroud for over

120 years. Now the cloth used on the World Championship tables is

branded as 'Strachan' (pronounce by the English as "strawns"!!)

An entry from the Thurston English

Order Book dated February 1889 - which, on the fifth line of

description says "finest superfine W. of England cloths"

In our collection we have a copy of a

booklet issued by Hunt & Winterbotham which was circulated by

Orme & Sons Ltd ( Link to Orme & Sons history) in 1924 (on

one of the copies Mr. E. A. Clare founder of the Liverpool firm had

written a dated noted about Orme's involvement). The information in

that booklet is still relevant to-day so we have transcribed it

below :-

Front Copy of

Booklet

Title Page -

'Concerning - Billiard Tables- especially CLOTHS'

Before the

written section starts this picture of 'Stud Merino' is

shown

THERE are many

points about a Billiard Table, which, provided the timber is sound

and well seasoned, do not greatly matter beyond the question of art

and style. There are, however, three points, viz : the slates, the

cushions, and the cloth, the perfection of which is absolutely

essential if the game is to be played in any degree

scientifically.

Of theses, three the slates may be trusted to

take care of themselves ; so may the cushions, provided they are

properly treated by the players, and that the temperature of the

Billiard Room is suitable and kept reasonably equable. But the

cloth is another matter, and from the very nature of its

construction demands regular care and attention of an intelligent

kind. The more the true nature of a Billiard Cloth is under. stood

the easier it is to keep it in just that perfection of condition

which ensures the perfect running of a ball, and without which no

decent game can be played.

It may be said at the outset that there is no

material, either animal or vegetable, which can provide so suitable

a surface over which a ball can travel with that truth, steadiness,

and quietness that the stroke demands, as does a fine woollen

cloth. It is because so few people interested in Billiards really

understand a cloth, that it gets so frequently blamed for troubles

for which it is in no way responsible. And yet, given a little

thought, it is possible so to understand it, or, to use an

expressive French term, so to "soigner" the table that the pleasure

and accuracy of the game are vastly increased.

A Billiard Cloth is not a piece of leather or

linoleum ! It is a delicately constructed fabric made on strictly

scientific principles, and the care of a cloth consists in the

continuance, in a minor degree, of just those principles and

processes which have been involved in the later stages of its

manufacture.

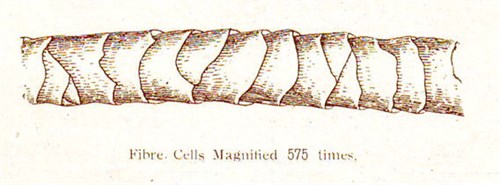

Every little thread in a bed length of

Billiard Cloth,-and there are some fifteen thousand, from the baulk

end to the top of the table.-is constructed of a mass of tiny

fibres, each of which in its turn is built up of delicate

microscopic cells, each hitting into, and overlapping the. other,

very much in appearance like the scales of a fish.

Now it is the

intelligent consideration for, and proper treatment of these fibres

which really matter in the care of a Billiard Cloth. Their

usefulness and perfection can easily be destroyed. They can be

bruised out of all recognition by hard, sudden pressure or blows,

-they can be torn and scratched by unsuitable and unreasonable

brushing -they can be scorched and burnt by a too hot iron till

their very nature and tenacity are destroyed, and they can be

seriously affected by continued damp. But given care and correct

treatment these little fibres will play their, part in the great

game of Billiards to the entire satisfaction of its most critical

exponent.

To come a little closer to detail. Beneath

the cloth is the slate-a surface hard and unyielding. Above the

cloth is the ball-with a consistency and substance of even still

greater resistance. I do not suppose that one player in a thousand

realises what he does when he throws a ball on to the table with a

fairly sharp concussion. The pressure which the cloth receives from

the impact between the unyielding surfaces of the ball and the

slate is sufficient to crush and bruise the fibre cells, thus

lessening their efficiency and usefulness, and incidentally

removing some of the nap from the surface, of the cloth.

The same thing is possible with a hard masse

shot or any similar or violent stroke. It must be remembered that

although the surface of a ball is round, yet the actual point of

contact with the cloth, or with an other ball, is infinitesimally

small, thus, having really a "cutting" effect, and given sufficient

impact will even cut clean through the cloth.

I have often heard it stated that these

little bare or grounded places which I have described as being left

on a cloth after some sharp concussion or impact, are caused by

moths. I have only to add that such an accusation is an unkind

libel on the habits of an insect which already has enough sins

lying at its door without including Billiard Cloths !

This liability of a cloth to " cut " under

extreme pressure is better understood when it is remembered at what

a great tension it is stretched over a slate. It is,or should be,

"as tight as a drum", and there. fore just in the condition to

render it liable to injury from any outside cause. If it were

merely lying normal, or at rest, as for in. stance like an ordinary

dining-table cloth,this liability would be very much

reduced.

In this connection I have purposely said

nothing as to the very common trouble of the shaving off of the nap

of the cloth by a cue tip, especially if the tip is ragged or

rough. Untold damage can very quickly be done to a new cloth in

this way, and it is the result either of gross carelessness or an

entire misconception "of how the game should he played.

The two methods adopted for keeping a cloth

in suitable condition for play are brushing and ironing, and the points

I have referred to in the first paragraph are intimately connected

with these two operations. Both of them, as I have said are the

continuation in a minor degree of processes of manufacture through

which the cloth passed in its final stages.

First as to brushing. I have seen

markers brushing a cloth hard against the nap (i.e. from the top of

the table towards the baulk end) or scrubbing it round and round

like a woman scrubs a stone floor. Both are fatal to the condition

of the cloth and in fact a new cloth may be so injured in this way

as to make it impossible to again "Set" the surface

properly.

The table should be brushed the running way

of the nap of the cloth, i.e. from the "D" end to the other, and in

doing so you merely follow the lines on which the manufacturer

produced the original nap on its surface. (It sometimes happens

that for some reason the cloth is reversed, the " D " end being

changed to the top of the table. In that case of course the above

remarks would not apply, as the cloth should then be brushed from

the top of the table to the baulk end).

Secondly as to ironing. This again is a minor

reproduction of a manufacturing process, viz : pressing.

An overheated iron has a directly injurious

effect on those little fibre cells which are the very life of the

cloth. It drives out of them the natural, or absorbed moisture

which they contain and which are necessary to their elasticity,

suppleness, and brightness,-leaving them dry and brittle, and far

less capable of standing the strain of play and brushing to which

they are continually subjected.

It is a truism that a really fine cloth "feeds" and improves

with age, and though that is an expression which may perhaps be a

little difficult to analyse scientifically, it is nevertheless the

result of experienced observation, and is closely connected with

the condition of the fibre cells. Excessive heat would entirely

prevent this and it is far better to go over a cloth three or four

times with a moderately heated iron, than once only with an iron so

hot as to produce the undesirable effect I have suggested.

There is at Dover a famous bronze Gun, cast

in Utrecht in 1544, and presented to Queen Elizabeth by the States

of Holland It bears an inscription in low Flemish which has been

translated, rather freely, in several ways. One version however,

reads - Charge me well, and sponge me clean, And I'll throw a ball

to Calais Green."

The point is that the gun undertook to do

certain work on certain conditions. So with a well made and good

quality Billiard Cloth. If properly and intelligently cared for it

will-do the work and play the part it has undertaken to do, and

those interested in its perfection and condition will find it will

well repay the trouble and thought given to it.

It would not be in the interests of the maker

of a Billiard Table that the cloth he supplies should last for ever

! But it is distinctly in the interests of his reputation that

those who purchase his tables should get the very best possible

value out of them, and it is solely with the object of assisting

them to do this that the foregoing remarks are offered.

So the booklet

ends.

However the production of woollen cloth from that

area goes back many more years than that. In "The History Of

Strachan & Co" written by Esther A. L. Moir in 1955, she writes

that 'it is abundantly clear that by the thirteenth century cloth

making was being carried out extensively here'. From those early

days all types of woven woollen material was produced from army

dress material to suiting as well as Billiard Cloth. Now the Stroud

mills specialise in Billiard Cloth & Tennis Ball Cloth.

The above is a

two side sales leaflet circulated by Thos Padmore & Sons

circa 1940

Front cover from

a cloth sample booklet sent out by Strachan's in the

1980's

Naturally our interest is in the Billiard Cloth production and

certainly the production of cloth for Billiard tables also goes

back through the centuries. Hunt & Winterbotham dates from the

1860's.

Billiard cloth

sample booklet issued by Hunt & Winterbotham circa

1950

In the 1920's Strachan, Playne and Hunt &

Winterbotham came together and traded as Winterbotham, Strachan

& Playne. This business later became a division of Illingworth

Morris a UK textile group and subsequently in 1990 a division of

Milliken Industries whose parent company in the USA enjoys a

similar history dating back to 1865.

A copy of a competition

sheet issued by E.A. Clare & Son Ltd. Circa 1940

which shows an old West of England trade mark with a 1646 date

within it. It is we believe associated with Hunt &

Winterbotham.

close up of the

Trade Mark

Strachan have provided some interesting 'old'

pictures not only showing how production was carried out but also

historical pictures of the mill building.

This water colour painting shows the

men at the bench hand teazeling the cloth with the boy fitting new

teazels to the tools.

Lodgemore Mill before

1871 Fire

Lodgemore Mill after

1871 Fire

Lodgemore Mill

rebuilt after 1871 fire

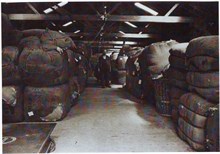

The following

pictures showing production are from a period just after the WWII

and show the old machinery and working methods.

The first picture

shows the Bales of raw wool as the are received from Australia and

are stored until required. The second picture is 'oiling the

wool' - Oil is applied to lubricate the fibres and aid the blendin,

carding and spinning.

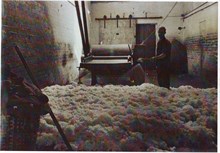

The first picture

shows the blending when the bales are opened and mixed. The second

picture is the carding - this seperates the wool fibers into a form

suitable for spinning into yarn.

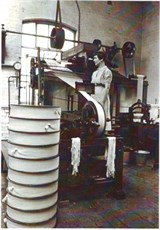

The first picture

shows 'Mule' spinning to produce the yarn. The second picture is

'section warping' - here the yarn is built into packages for

presenting to the loom for weaving.

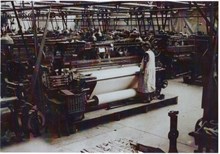

The first picture

is the weaving floor. Shuttle looms insert the weft threads and

creates the 'grieg' cloth which is in the 'white'. The second

picture shows 'mending /burling the cloth. The cloth is inspected

and knots removed and faults in the weave corrected.

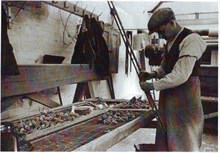

The first picture

shows teazel setting. A teazel is a type of thistle head and is set

into a frame. The frames are fixed into a raising machine which

will creat the nap, sheen and lustre on Billiard Cloth. The second

picture is 'Fulling' - this process combines heat, moisture and

friction to shrink the and felt the cloth.

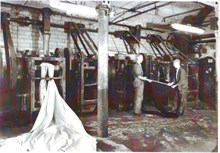

The first picture

is a Teazel gig which is used to lay the nap.The second picture

shows the Billiard cloth being 'Wet Brushed'. Both Processes

are used to lift and lay the directional nap on Billiard

cloth

Billiard cloth in

the dyeing room

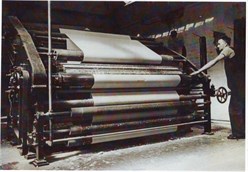

The first picture

shows billiard cloth being 'sheared', this process ensures a

uniform length to the nap and adds lustre to the cloth. The second

process show the cloth being dried.

Strachan West of

England cloth uses only the finest Merino wools from Australia

carefully selected according to very precise specification and the

woven"greige" (the rough cloth) is put through a series of

complicated specialised processes such as "raising" or "teazeling".

To raise the face of the cloth and give a direction or "nap" and

"milling" which provides the body or weight. After these processes

the cloth is transformed into a highly engineered fine billiard

cloth featuring the napped lustrous characteristic of Strachan West

of England.

Strachan West of England cloth has been chosen by

the Professional Billiards & Snooker Association for use at all

major snooker and billiard tournaments, including the prestigious

World Championships since 1980

Acknowledgements - Strachan West of England

for providing much historical information as well as many of the

pictures used in the article.

The story of the West of England

Billiard Cloth continues :-

Textile manufacturer (Strachan Snooker &

Pool Cloth) returns to UK

ownership

In

2011, twenty years after it was bought by US based Milliken &

Company, the Stroud textile business Milliken Woollen Speciality

Products (Strachan) has proudly returned to British

ownership.

The

business has been christened WSP Textiles Ltd, with three senior

members of the management team joining a new board of

directors.

The

former Milliken WSP management team who have seats on the board are

the new chief executive David Smith, sales director Duncan Kettell

and manufacturing director Malcolm Fallows.

The

acquisition was arranged by Vespa Capital LLP, a private equity

firm that helps management teams acquire and develop the businesses

they manage.

The

original company had made cloth since the 13th century

and the WSP acronym recognises the founding mill owners, Messrs

Winterbotham, Strachan and Playne.

Today

the Strachan brand dominates the snooker market while Playne tennis

ball cloth can be found on Dunlop, Wilson, Head, Tretorn and

Babolat tennis balls used at many tournaments including Wimbledon

and the French Open.

The famous Strachan (West of England) cloth has now been used at

all WPBSA / World Snooker events, including the World

Championships, since 1980 and ofers all levels of player the

ultimate playing surface. All Strachan snooker & English pool

cloths use 100% wool and are made in a very traditional

way using many ancient techniques whist blending this with todays

modern quality standards.

Strachan 2012 Snooker Cloth brochure

….......................................

Thurston offer a full

service for the recovering of Snooker, Billiard, Pool tables and

also for Bagatelle and Bar Billiard Tables using both Strachan West

of England cloth and Hainsworth cloth. Thurston also offer a

comprehensive maintenance contract and are able to supply all the

accessories for Snooker, Billiards & Pool.

Just call -

44(0)151 482 2700 or visit www.thurston.co.uk

© E.A. Clare & Son Ltd.

2018. © Peter N. Clare 2018

Reproduction of this article allowed only with the permission from

E.A. Clare & Son Ltd.