Article 2 - Re-Testing Lawn Bowls

ARTICLE 2 - Testing

Bowls (Originally published in 1997 and revised in 2009)

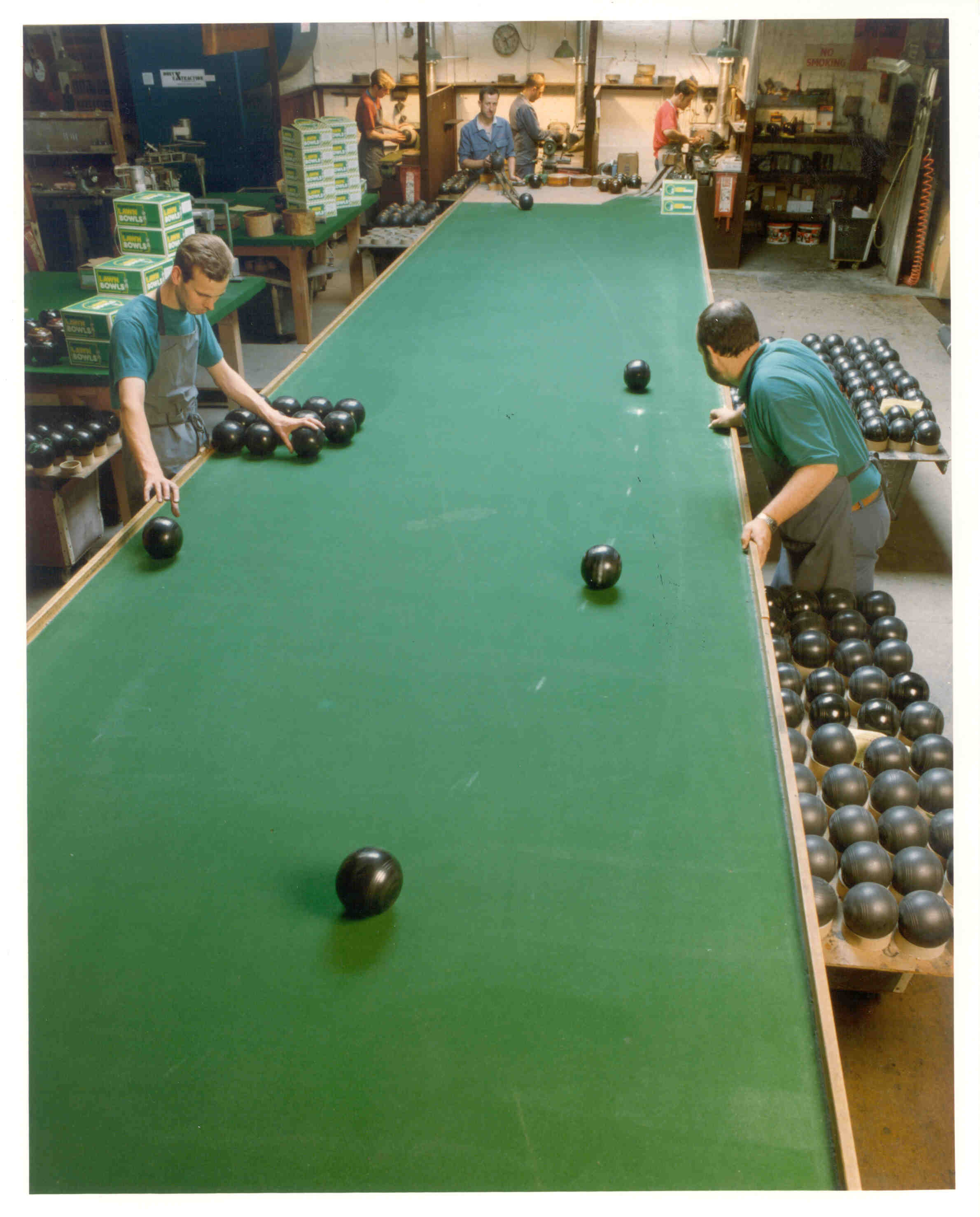

a view of the Drakes Pride test table

In my first article, I mentioned the importance of 1871 - well

that was the year that Taylor's of Glasgow constructed the first

testing table. I understand, from speaking to Noel Taylor that the

idea was to allow the company to produce matched bowls from their

factory rather than waiting for the customer's vague instructions

and comments as to their requirements.(I should mention here that

unless otherwise stated this article refers to the bias for lawn

bowls and the authorities for that discipline)

A test table allows the production of bowls that perform on the

test table (note the wording 'on the test table') in a given manner

and at that time these were specified as number 1 bias through to

number 5 bias. Number 1 bias being the weakest and number 5 the

strongest. But when the Scottish Bowls Association carried out

their testing, they were then able to agree upon a bias strength

and thus in 1893 adopted the number 3 biassed bowl as their

'Standard'.

I am sure that there are a lot of bowlers who will remember the

reference to number 3 bias, which was still regularly mentioned up

to a few years ago. Crown green bowlers will also note that their

standard was selected using the same five biases and that the

number 2 was considered not strong enough, but number 3 bias was

too strong. Thus,2 full or slightly stronger than 2 bias was

selected. I have not been able to find any information as to the

date when the crown green bias was selected.

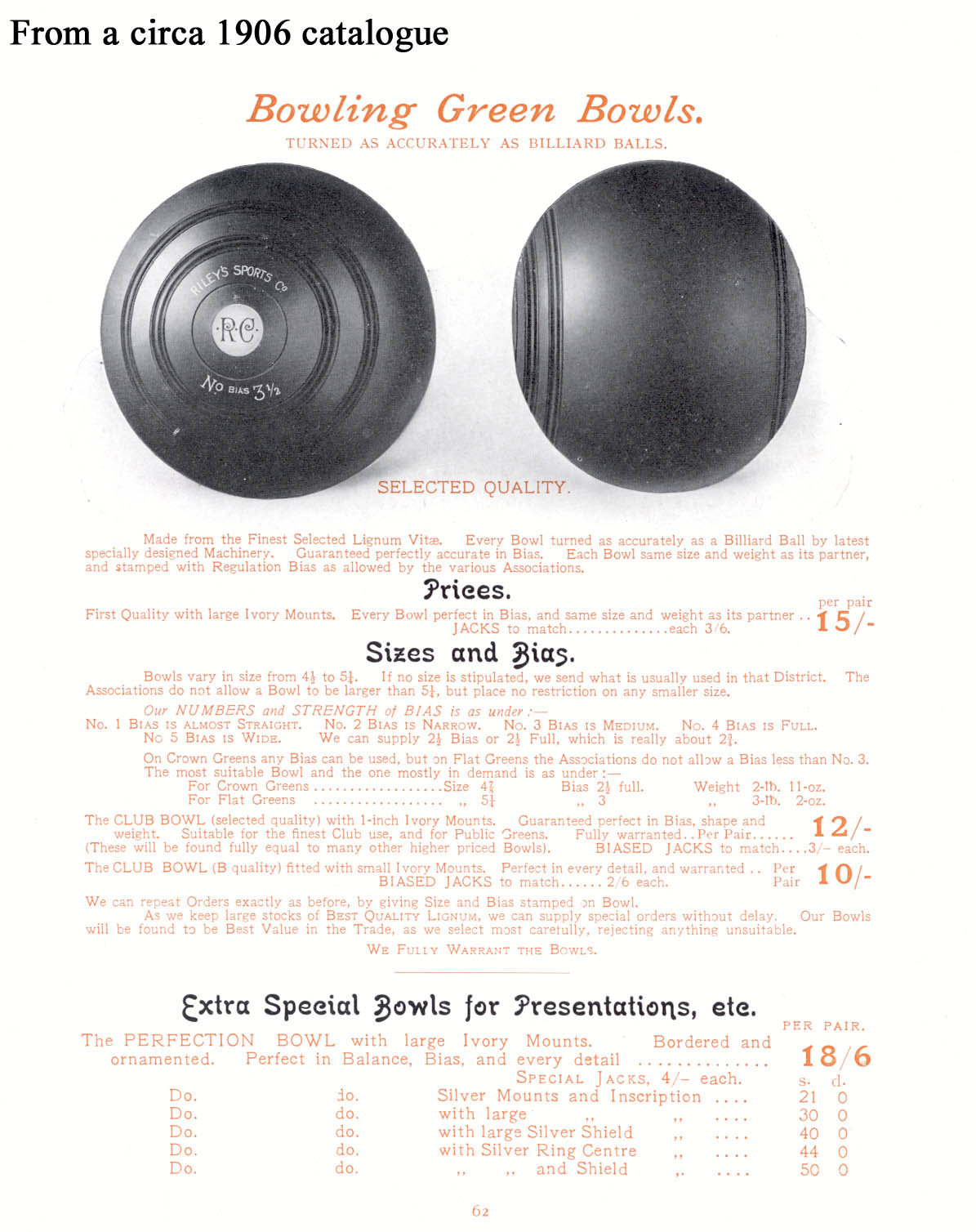

Interestingly in further research during 2002 confirmation of

the 1 bias to 5 bias still being available in the 20th Century was

found in a circa 1906 catalogue. A copy of the page is shown

below.

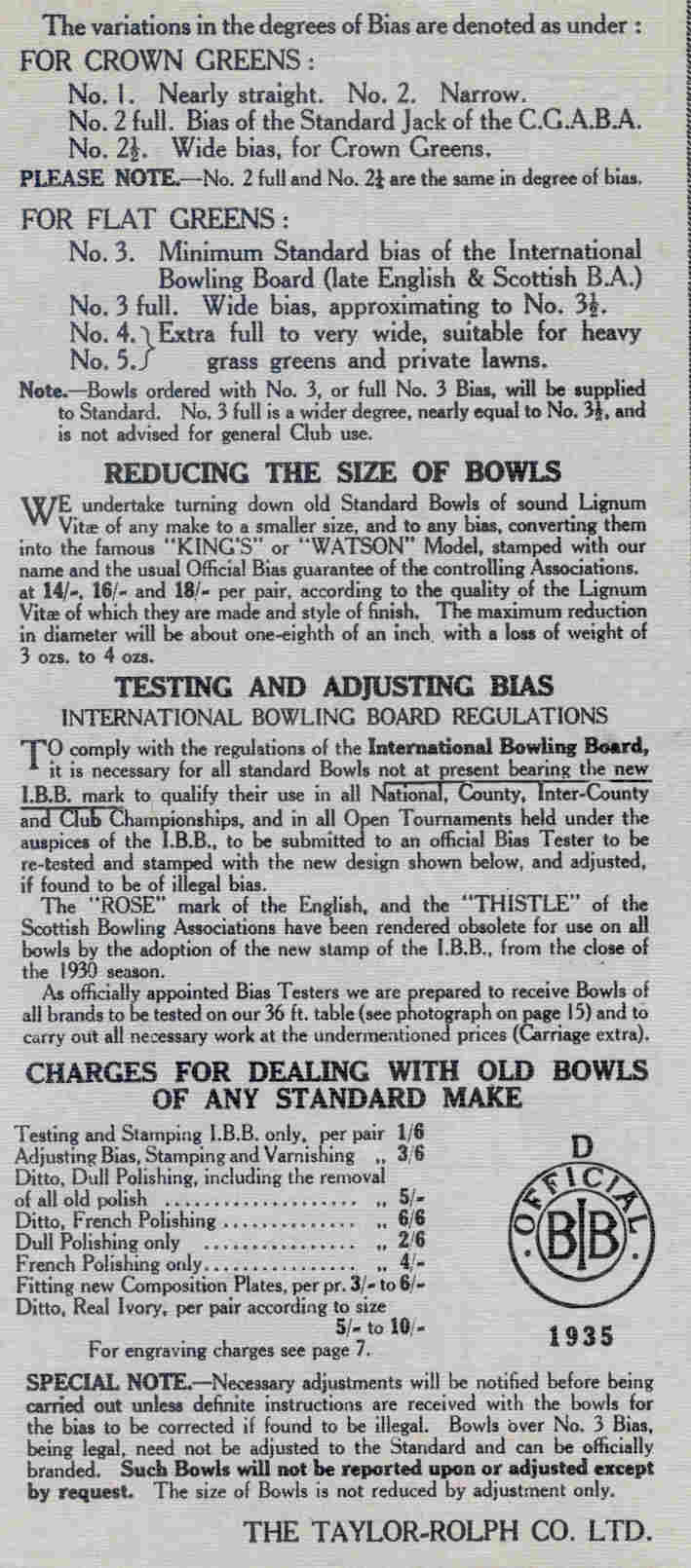

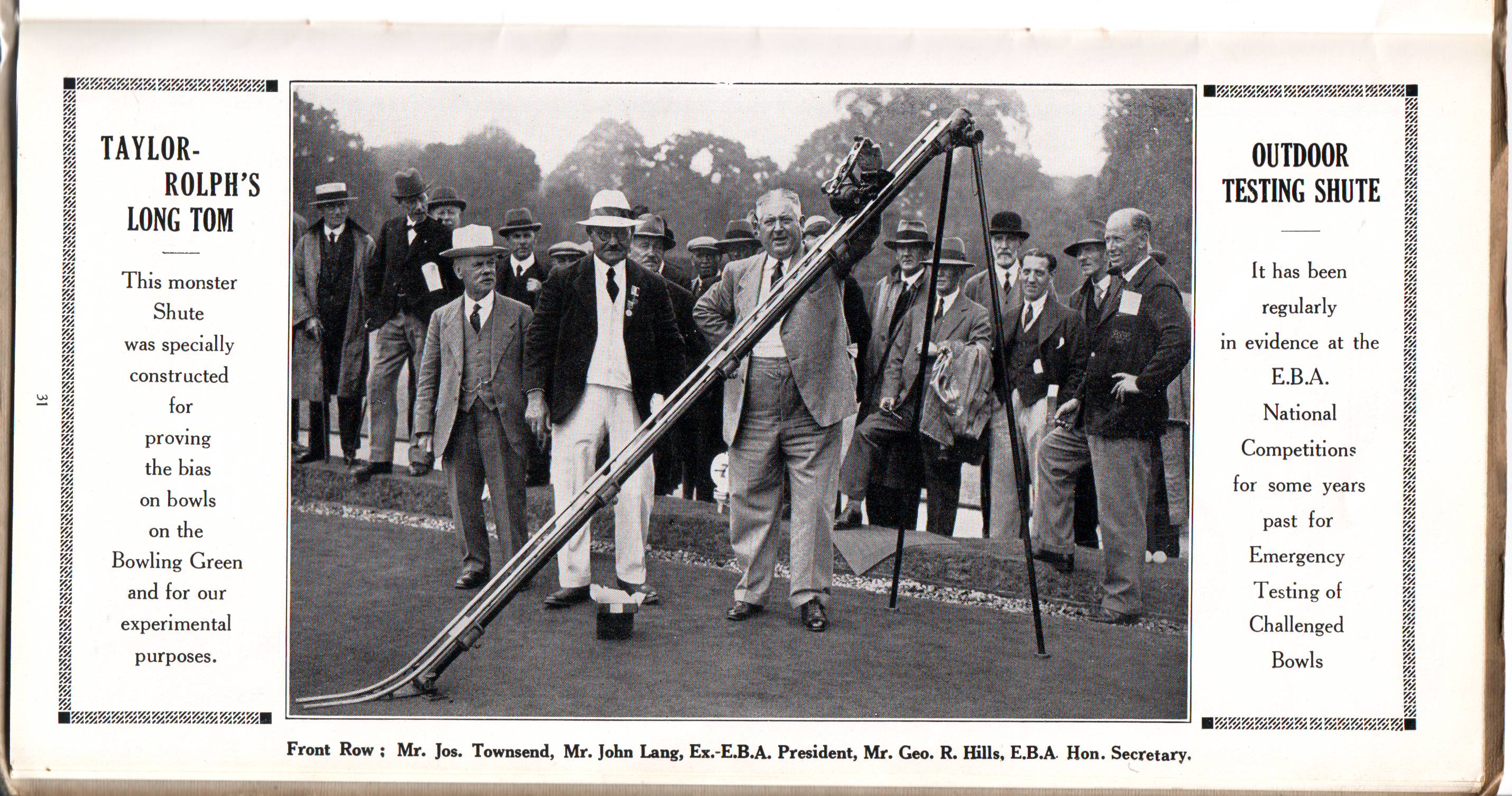

The next picture is taken from a 1935 price list of Taylor-Rolph

and still lists 5 strengths of bias. However it is interesting to

note that biases 1 through to 2 ½ are notes as Crown Green

Bias.

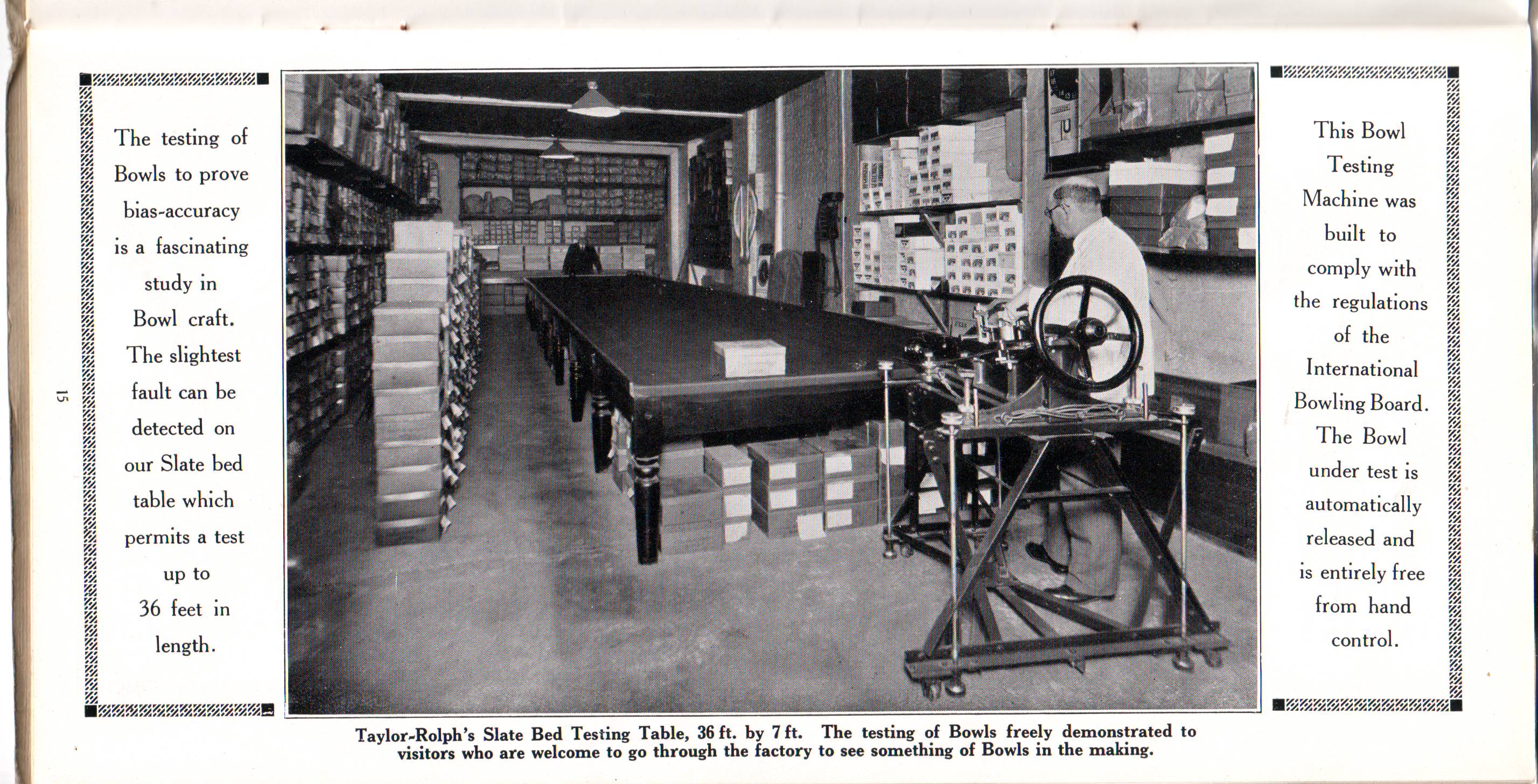

Nearly all test tables have been and are based on standard

billiard/snooker tables, because of their rigidity of construction

and the accuracy of level that the slate bed can achieve. Thurston,

Drakes Pride sister company, has in fact installed a number of

these test tables both in the UK and Australia, and so they are

considered to be the experts on test tables. In the Hensell booklet

"The Romance of a Bowls Manufacturer" it mentions the fact that W.

D. Hensell tested bowls originally on a standard (12ft) billiard

table, but in 1908 developed a 36ft test table. This basically

would be achieved using three full size billiard tables placed end

to end, the cushions being removed to give one long table. Perhaps

it is worth mentioning that there is a remarkable association

between Bowls manufactures and Billiards. It was whilst working for

the Australian Billiard business of Alcock Thomson & Taylor

that Hensell first worked on bowls.

In 1928 an attempt was made to lay down test table performance

so the fact that in the 1935 Taylor- Rolph catalogue they showed

their test table indicates the significance placed on the means and

method for testing.

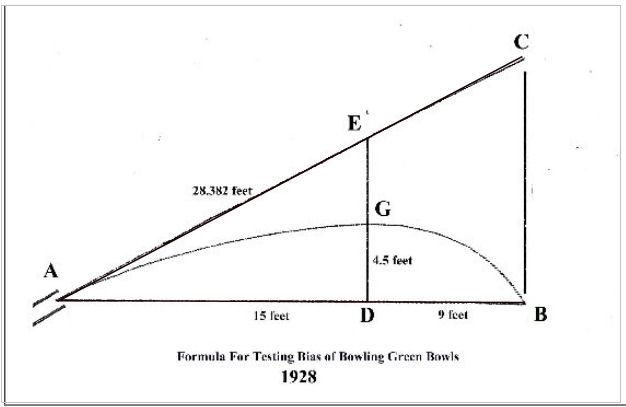

In 1928, the I.B.B. (International Bowls Board changed to World

Bowls Board and currently the World body is - World Bowls Ltd.)

laid down the basis for table testing (See drawing and the

specifications, which with a few amendments are basically still

true today. For example, the bowls should still run approximately

28 feet, themaximum draw shall be approximately

4'6 however, one important addition to the specifications is that

the running time should be between 12 - 15 seconds.(note on 2002

the governing body of Lawn Bowls ,World Bowls Ltd., laid down

regulations which stipulated that the length of run was 9

metres)

1928 Dia. For Bias Testing

NOTES TO ACCOMPANY THE REGULATIONS FOR TABLE TESTING OF

BOWLS

The I.B.B. Official Bias Testers formula for testing in October

1928 set out the following points :

(a) For the purpose of accurate testing the table must consist

of an impervious material so that it would be independent of the

variations of temperature.

The cover to be made of the same texture throughout without

joins. We suggest that this should be obtained from the I.B.B, thus

ensuring that all tables will be covered by the same cloth, no

other fabric being permissible for testing purposes.

(c) That a straight line A - C of 28.302ft be drawn to extend

from the middlepoint of the mouth of the chute and parallel to both

it sides.

(d) "A" being starting point of the bowls contact with the

table.

Sub-tendon angle ABC equal to 90 degrees so that AB is 24ft and

CB is 15ft.

(e) Let DE be a point on AB so that AD is 15ft and OB is 9ft

From D straight line DE in drawn perpendicular to AB to meet AC

at E

(h) The track of the bowl will then leave point A pass through

an agreed point G on the line DE and finish on the line AB at

3.

(i) Point C will he determined at the discretion of the I.B.B.

and will then indicate the minimum standard bias for bowls.

NOTE : On the basis of the E.B.A.(English Bolws Association)

standard bowl submitted to us, the distance DG will be 4ft 6in on

the present test table. The same standard bowl draws, on a careful

trial, on a dry day in average conditions on Queens Park Green,

Glasgow 5ft 6ins.

FURTHER NOTES : (From Mr. C. S. White of Exeter 16th October

1928)

"My observations of the diagram is that we are presently

following that out to the letter, only that the EBA standard is a

little wider at point G. As regard to the formula I do not agree

with the table on account of vibration. Mine is a 6ft. concrete

floor 35ft x 7ft finished long and smooth, damp proofed, coated

with a seamless baize, with a 5ft chute of all metal construction

all of which I find work very consistently. Of course in testing a

bowl on a hard floor, there is only half the running surface in

action compared with a proper green. I get bowls of different makes

to put right occasionally, although they bear the official stamp

and also pass the test on this floor yet they were not consistent

on the green.

My suggestions (Mr. C. S. White of Exeter) are these, if I

may:

Each testers must be an actual bowl maker. That all the testers

are supplied with a master bowl all exactly the same manufacture,

(I prefer, T. Taylor Glasgow) and that they be sent back, at least

once a year to verify correct."

The above observations particularly about differences

between test tables performance and the green is, from the writers

point of view, still very true to day. In other words the test

table is a tester quality control device rather than a scientific

means of testing a bowls performance in use.

Returning to bias, there is, however, as most are aware a lot of

controversy over "straight running" bowls. The W.B.B. together with

the manufacturers have been working extremely hard, over recent

months to find a solution. One immediate problem that quickly

became apparent was that the existing specifications were too

widely drawn and so it was possible to get different results on

different tables, although these differences were in the bounds of

reasonable tolerances.

It should be noted however, that a number of manufacturing

companies, mine being one, argue that the test table is and always

has been a quality control devise, rather than being an absolute

test for bowls performance. It does not, and can not be expected to

show how a bowl performs on the green. Yes, a well trained and

experienced tester would be able to judge, but bowls, as all

bowlers know is played on varying surfaces, running at various

speeds, in varying conditions and the bowls themselves are

delivered in a variety of manners. Bowls is not played on a series

of billiard/snooker tables, released down a chute and run over a

short 28ft.length. (now 9 metres)

In Australia, were they seem to enjoy challenging each others

bowls, they, in my mind wrongly use the test table as the arbiter.

I feel that the only true test of a bowl, whether a challenge has

been made or not, is on the green. I believe that the W.I.B.C.

basically have the same thoughts. If, a challenge has been made,

then the only place to test the set of bowls is on the actual

rinkthat the challenge was made on. It is possible for bowls to

fail on a green test and pass on the table, and visa versa, pass on

the green and fail on the table. Which is right? - I believe that

the bowl that passes on the green is correct, even though I do

accept that green testing is a very difficult process, and requires

not only a lot of experience, but a lot of training an well.(Green

testing of any form is not recognised by World Bowls Ltd. as a

legitimate test)

The picture is taken from 1935 Taylor-Rolph price list. It is

worth noting that it was also used for the emergency testing of

'challenged' bowls

When the writer visited New Zealand in the mid 1980's their only

method of testing was to use a chute and the picture below shows

the chute used at a Dunedin green. It was not until 2002 that a

World Bowls Ltd. licensed test table was set up in New Zealand.

The following picture was published in the Queensland Bowler

magazine in September 1998 and shows that some green testing was

also carried out in Australia

However, one very important point that affects the bowls

performance, is the bowlers own style of delivery. An example I now

regularly use is from a visit to Australia when I was called over

to a green by two players. They were both playing Drakes Pride

bowls, size 5 heavyweight, one with a grip and one that was plain,

and I was asked why the grip bowls took less land than the plain. I

naturally replied that it was not true, so they bowled the two sets

and sure enough the grip bowls took about 14" - 18" less land. This

I had to admit did cause me some surprise and so I asked them to

swap their sets and bowl again. This time, it was their turn to be

surprised to find that the plain bowls now took 14" - 18" less land

than the gripped. The only thing that has changed was the bowler,

and whilst a trained coach might well have been able to spot what

was the difference between their deliveries, I could not. The

results just confirmed that the bowlers themselves make a

difference to the bowls performance, not just the work that we

manufacturers do.

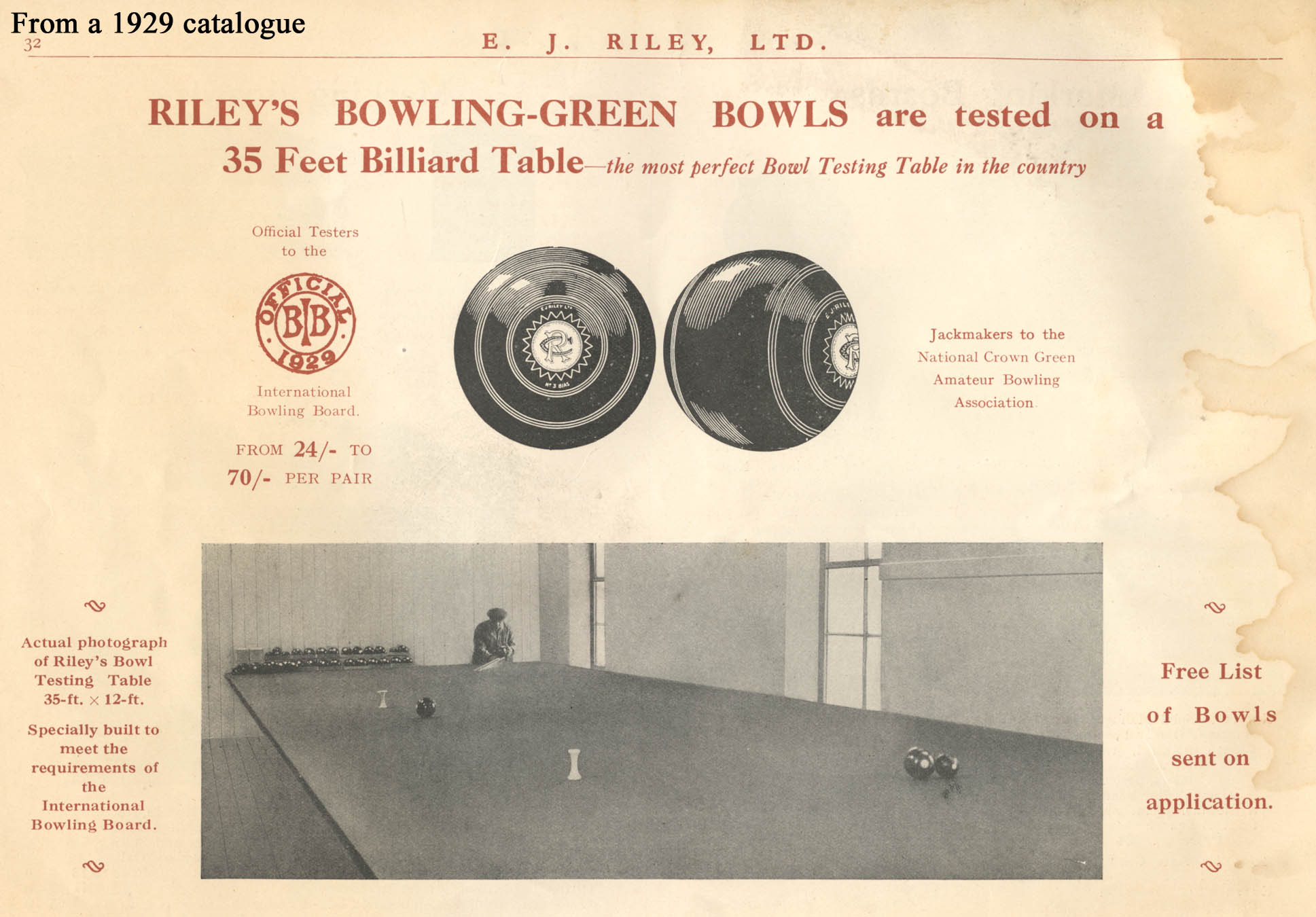

The picture above is from a 1929 catalogue and shows a 35ft x

12ft Bowls test table. It must have been made from 6 full size

billiard tables. Note also the International Bowls Board stamp with

a 1929 date stamp.

In April 2002 World Bowls Ltd. introduced a revised Working

Referance Bowl at the same time as establishing a standard test

table surface, a standard release chute,

a WorkingReference

Bowl (WRB) and Test Regulations to be followed.

The 2002 Regulations are not too dissimilar to the 1928 formula, or

the previous 1986 Guidelines although the test distance is now 9

metres. World Bowls Ltd. have a specified delivery chute which must

be used and also inspect the test tables every year and at the

inspection exchange the Working Reference Bowl that is issued to

the tester / manufacturer.

Frequently asked questions

about Lawn Bowls

Question. I have a set of

Lignum Vitae (wooden) bowls can they be re-stamped ?

Answer. World Bowls have tightened up their

regulations and it is now unlikely that Lignum bowls will conform

to those regulations. However the bowls can still be renovated and

used in social games despite not being stamped.

Question. The date stamp on my

bowls has expired, do I really need them to be re-tested

?

Answer. The World Bowls

'stamp' and its predecessor World Bowls Board 'stamp' have a ten

year life, which includes the year of its test. So basically by

their regulations the answer is, yes it should be re-tested. The

main reason for doing the re-test is that part of the work done

checks that the set is still running as a set. After all given ten

years of wear and tear the bowls must have suffered abrasion and

knocks. So it is in your interest to have them checked

out.

Question. My bowls have no

emblems, are they legal?

Answer. This question

basically only relates to sets sold in the UK prior to 1996, when

emblems were not required in the UK. Even now it depends on what

level you are playing at to know if emblems/engraving is required

for play in the UK. This needs to be considered and advised to the

tester when you submit your bowls for test. Currently (2009 - still

true in 2013) the World Bowls Ltd. testers licence states ' Bowls

may display- Engravings (emblems)'. However, the manufacturers

licence requires all sets to have engraving (emblems), so all new

sets of bowls will have emblems.

For club and even inter club

competitions bowls without emblems are ok. If however the

competition is under the auspices of World Bowls Ltd. or the

Professional Bowlers Association the you will find that sets of

bowls must have emblems. So to be safe it is probably best to have

emblems/engraving.

THURSTON can engrave emblems

on to most makes of bowl and would suggest that this work is

carried out at the same time as the set is tested.

Question. I've decided to have engraving on my

bowls, can I have my initials and an emblem?

Answer. The answer is yes, but with

reservation. As long as the initials are all on the same side eg.

on the bias side and the emblem on the non bias side. Then the

sets, basically, conforms to World Bowls Ltd. regulations and will

be acceptable in the UK. Most other counties require that the

emblem would be the same, but proportional in size, on the bias and

flat side of the bowls.

THURSTON recommend that the

emblems/engraving be the same on both sides which avoids any

possible future problems.

Question. I play outdoors what weight of bowl

should I use?

Answer. If you only play outdoors and play in the U.K.,

then a medium weight bowl is probably the best. The reason being

that most U.K. outdoor greens are slow / heavy and a medium weight

bowl will have some chance to show its bias. If you were to use an

Indoor style and or heavyweight model the slow / heavy greens will

kill the bias before it has a chance to show.

Question. I play both Indoor and Outdoor do I

really need to different sets of bowls ?

Answer. The previous answer has some bearing on

this one. However there are some models of bowl (eg Professional by

Drakes Pride) that have medium bias and many bowlers find they

perform acceptably both on outdoor and indoor greens. Most

manufacturers do however produce models suited to either outdoor or

indoor use. Note. If outdoor model bowls are used indoor they will

tend to run into the next rink and so you might not be able to play

certain hands. If indoor models are used outdoor they will show

little or no bias and reduce the game to playing up the middle.

Perhaps this is what causes complaints about bias strength

?

Question. What size of bowls should I

use?

Answer. The 'old' idea was to use the largest

size you possibly could, or that if you can span the circumference

of the running sole with your two hands then that size would be

right.

However the simple answer is

whatever size feels comfortable in the hand. So when selecting a

set of bowls try a few sets. Perhaps start with a size 3 try a few

'pretend' deliveries. Does it cause any strain to your wrist? Does

it feel that you need to adjust /tighten you grip in the back

swing? Does out fall out of your hand!? If it all feels ok then

perhaps try a size 4 or even larger, but if there is discomfort go

down the sizes until you are comfortable.

Also there are some models'

which are not as broad, such as the Drakes Pride Professional

model. Such models might allow you to use a bigger bowl

comfortably, so also try a few types of bowl in a size if you

can.

Question. I

have two sets of the same make and model of bowl one set

is red the

other is green. I am

told they are the same bias but I find they take a different line -

whose is right?

Answer

. Speak to any of the top bowlers and

they will agree that the different coloured sets perform

differently and yet when seen on the bowls test table they run the

same. The only answer that seems to have any merit is that subtle

but significant differences in how the player grips the bowl and

thus how they deliver. Are probably caused by affect that the

different colour dyes used in the powder mix used for moulding

bowls has on the final surface finish.

Question. My

set of size 4 heavy bowls weigh more than my friends set, why is

their a difference?

Answer. We

assume that the sets are different models or are from different

manufactures. As each manufacturer uses the specific gravity of

moulding powder that they favour for their quality. So there are

likely to be weight differences between different manufactures

sets. Also there is likely to be differences between models as

there are some that are slim line, so slightly less material, and

some which 'fill the hand', which will have a little more material.

So between different models from the same manufacturer there will

be different weighs, even if both are marked up as 'heavy', for the

same size bowl. The

weight chart shown below should therefore be used as a rough guide

only.

Question.

It looks like they have painted

the grips on their bowls, surely this effects the bais and is it

allowed?

Answer. Law 8.6 deals with alterations to bias

of bowls which is illegal and has sever penalties. However point 4

states .. Players or owners who colour the groove rings or dimples

on a bowl for decoration are not breaking the

law.

This size/weight table is an

approximate guide to weights and sizes of lawn bowls, each

manufacturer and each model will be somewhat different. These

figures are only for guidance and are an average across a range of

models & makes.

-

|

Size.

|

Dia

|

Medium weight

|

Heavy Weight

|

Extra Heavy

|

|

00

|

116 mm

|

1.19 kg

|

1.25 kg

|

1.27 kg

|

|

0

|

118 mm

|

1.22 kg

|

1.28 kg

|

1.30 kg

|

|

01

|

119.5mm

|

1.28 kg

|

1.33 kg

|

1.36 kg

|

|

1

|

121mm

|

1.30 kg

|

1.35 kg

|

1.40 kg

|

|

2

|

122.5mm

|

1.35 kg

|

1.40 kg

|

1.44 kg

|

|

3

|

124mm

|

1.40 kg

|

1.46 kg

|

1.50 kg

|

|

4

|

125.5mm

|

1.46 kg

|

1.52 kg

|

1.55 kg

|

|

5

|

127mm

|

1.52 kg

|

1.58 kg

|

n/a

|

|

6

|

128.5mm

|

1.58 kg

|

n/a

|

n/a

|

|

7

|

130mm

|

1.58 kg

|

n/a

|

n/a

|

Unless otherwise stated the pictures used and scans are

copyright to E.A. Clare & Son Ltd.

© Peter Clare 2009 - © E.A. Clare & Son Ltd. 2018 -

reproduction of article allowed only with permission from E.A.

Clare & Son Ltd.