Article 3 - Bias

ARTICLE 3 - Bias

(Originally published in 1997 and

revised in 2009 & 2019)

Bias The Oxford English Dictionary considers the first use of

the word, as follows "Originally an adjective, as in PR. "Via

Biayssa" - cross or oblique road". The seamstresses amongst you

will also recognise the use "on the bias" -being "diagonally,

across the textures". The dictionary does say that the word became

the technical term at the game of bowls, whence comes all the

latter uses of the word.

So we can see that 'bias' comes from the bowl running obliquely

to the line on which it was delivered. Again, referring to the

Oxford English Dictionary, there are two very good paragraphs which

are worth bringing to this article. They are as follows "a term of

bowls applied a like to : the construction or form of the bowl in

parting an oblique motion..... thus a bowl is said to have a wide

or narrow bias. The second makes mention as follows "formally bias

was given by loading the bowls on one side with lead and this was

itself sometimes called the bias..... ..... they are now made of

very heavy wood and the bias given entirely by the shape, which is

that of a sphere slightly flattened on one side and protuberant on

the other, as if composed of the halves of an oblate and prolate

spheroid".

Well that has helped my education !!! but I wonder about the

artificial weighting - certainly the story about the Duke of

Suffolk's experience in 1522, may support it. Although, I always

understood the significance of the story of when he discovered that

his hastily cut bowl from the bannister post, having bias was thus

able to "go round" the blocking bowls and giving him an advantage.

I feel indicating that the other opponents bowls actually ran

straight, not having bias introduced by another means..

Just a note, all artificial weighting is illegal - despite this

when bowls come in for service, there are still some bowls that

people have tried to 'adjust' the bias with loading.

The simplest way to show the bias effect and produce same is to

take a snooker ball and produce a flat on one face and then run

that ball on the table. Such a ball rolled along the table will

turn away from the ''flatten" side, (just as for the Duke of

Suffolk) and you have thus produced a biassed ball. Basically the

side which has been ''flatten" is now lighter than the other side

so the ball falls to the heavier side - the centre of gravity of

the ball has been shifted from the centre of the ball.

This the simplest method of producing bias as described,

obviously has to be modified for the production of a bowl so that

the bowl can be comfortably handled.

Originally, with Lignum Vitae, (wooden) bowls the shift in the

centre of gravity, used to produce the bias was more easily seen by

the bowler. The reason being that as the timber is has a specific

gravity of about 1.32 it needs a larger percentage of its mass to

be 'off centre' to produce the bias. The more modern phenolic bowls

using higher specific gravity material than Lignum Vitae means that

that shift in the centre of gravity is visually less obvious, but

is still there nevertheless.

However, the bias can also be produced

by adjusting the running sole, and any of you that have had your

bowls adjusted will know that this in the method used to produce a

change in a bowl to a required bias. At the Drake Pride factory,

because we renovate large numbers of Lignum Vitae bowls (for the

Crown Green players) where basically every set has to be re-biassed

during renovation procedures, we therefore, have great experience

and skill in the intricacies of hand biasing. However, as we now

are producing the modern phenolic bowls on computer controlled

lathes, it means that another set of skills is required to ensure

that the bowls run as the manufacturer requires.

In 2019 Jean and Maurice Roger of

Pershore Bowls Centre donated several items to the Bowls Heritage

Collection. Amongst the items Was a booklet published by

Taylor-Rolph in 1938. In the booklet was an interesting article -

titled "What is Bias"

It is worth reading so a copy is below:-

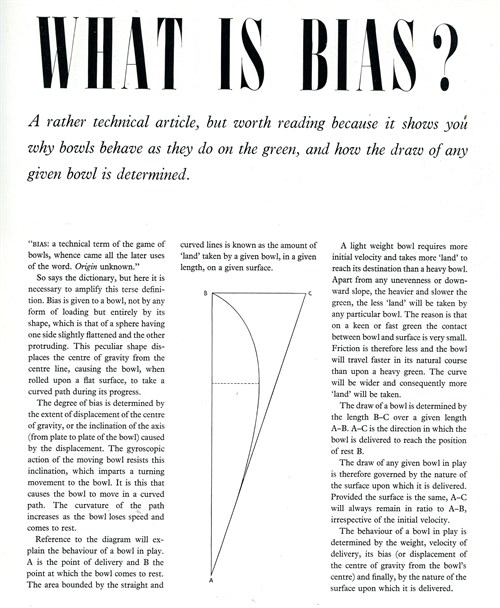

WHAT IS BIAS ?

A rather technical article, but

worth reading because it shows you why bowls behave as they do on

the green, and how the draw of any given bowl is

determined.

"Bias: a technical term of the game of bowls, whence came all

the later uses of the word. Origin unknown."

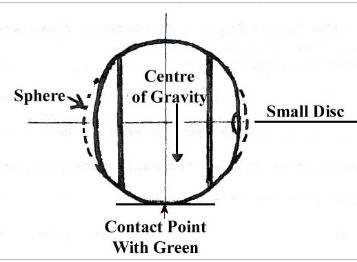

So says the dictionary, but here it is

necessary to amplify this terse definition. Bias is given to a

bowl, not by any form of loading but entirely by its shape, which

is that of a sphere having one side slightly flattened and the

other protruding. This peculiar shape displaces the centre of

gravity from the centre line, causing the bowl, when rolled upon a

flat surface, to take a curved path during its progress.

The degree of bias is determined by the

extent of the displacement of the centre of gravity, or the

inclination of the axis (from plate to plate of the bowl) caused by

the displacement. The gyroscopic action of the moving bowl bowl

resists this inclination, which imparts a turing movement to the

bowl. It is this that causes the bowl to move in a curved path. The

curvature of the path increases as the bowl loses speed and come to

rest.

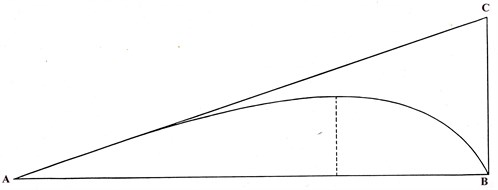

Reference to the diagram will explain the

behaviour of a bowl in play. A is the point of delivery and B the

point at which the bowl comes to rest. The area bounded by the

straight and curved lines is known as the amount of 'land' taken by

a given bowl, in a given length, on a given surface.

A

light weight bowl requires more initial velocity and takes more

'land' to reach its destination than a heavy bowl. Apart from any

unevenness or downward slope, the heavier and slower the green, the

less 'land' will be taken by any particular bowl. The reason is

that on a keen or fast green the contact between bowl and surface

is very small. Friction is therefore less and the bowl will travel

faster in its natural course than on a heavy green. The curve will

be wider and consequently more 'land' will be taken.

A

light weight bowl requires more initial velocity and takes more

'land' to reach its destination than a heavy bowl. Apart from any

unevenness or downward slope, the heavier and slower the green, the

less 'land' will be taken by any particular bowl. The reason is

that on a keen or fast green the contact between bowl and surface

is very small. Friction is therefore less and the bowl will travel

faster in its natural course than on a heavy green. The curve will

be wider and consequently more 'land' will be taken.

The draw of any given bowl in play is

determined by the length B - C

over a given length A-B. A-C is the direction in which the

bowl is delivered to reach the position of rest B.

The draw of any given bowl in play is

therefore governed by the nature of the surface upon which it is

delivered. Provided the surface is the same, A-C will remain in

ratio to A-B irrespective of its initial velocity.

The behaviour of a bowl in play is

determined by the weight, velocity of delivery, its bias (or

displacement of the centre of gravity from the bowl's centre) and

finally, by the nature of the surface upon which it is

delivered.

The article "What is Bias?"was

published by Taylor-Rolph in 1938

All manufacturers now use computer controlled. lathes (Drake

Pride being the first company to install such equipment) and

therefore the modern bowls no longer require hand biassing as the

programmes that are used produce the 'total' geometric shape of the

bowl. This may incorporate some shaping of the running sole, but

all the shape is produced on the lathe, combining with the gravity

shift and the mix of how these two basic methods are used is how

the different manufacturers produce the different handling

characteristics of their models.

From an interesting old book 'The Physics of Ball Games" there

is a section on "the path of a a wood" across a bowling green, and

this is worth producing as in relatively simple terms it does

explain how the curved path of the bowl is produced.

THE PATH OF A 'WOOD' ACROSS A

BOWLING GREEN:

Fig B.

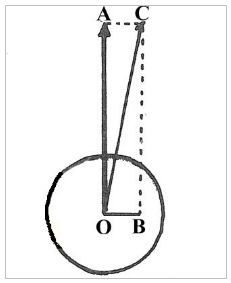

The fact that a bowls 'wood' which has

bias pursues a curved path across the green is a result of the

principle of conservation of angular momentum, and its motion is

best explained on that basis.

However, it is fairly easy to accept, at least in general terms,

why it behaves as it does.

Fig. B is meant to represent such a wood, seen from above,

rolling across a green in the direction of the arrow OA.

Since it is rolling, the top of the wood will be moving with a

velocity in this same direction. Suppose the bias is on the right;

that is to say, the centre of gravity of the wood Is to the right

of its centre. Then this bias will tend to rotate the wood over

from left to right, and so give the top of the wood a small

velocity in the direction OB This, combined with the very much

greater velocity along OA will give a combined velocity somewhat to

the right of OA-along OC. It is therefore in this direction that

the wood will tend to roll. In this way it will always tend to roll

slightly to the right of the path on which it finds itself. In the

early stages, when it is rolling rapidly forwards, the velocity

along OA is very much greater than that along OB, and so the

curvature of the path will be slight. Later on, as it slows down,

the transverse velocity becomes relatively more important, and the

curvature in the path gets greater and greater, until the bowl

eventually stops rolling and comes to a halt.

In 2019 Jean & Maurice Rogers, the owners of Pershore Bowls

Centre kindly donated to the Collection bowls items. One of which

was a booklet title BOWLS published by The Taylor -Rolph Company

Ltd. in 1938. In it was an article titkes 'What is Bias' and so we

thought it worth adding to our 2017 article and is shown below

:-

© Peter Clare 2019 - © E.A. Clare

& Son Ltd. 2019 - reproduction of article allowed only with

permission from E.A. Clare & Son Ltd.

I